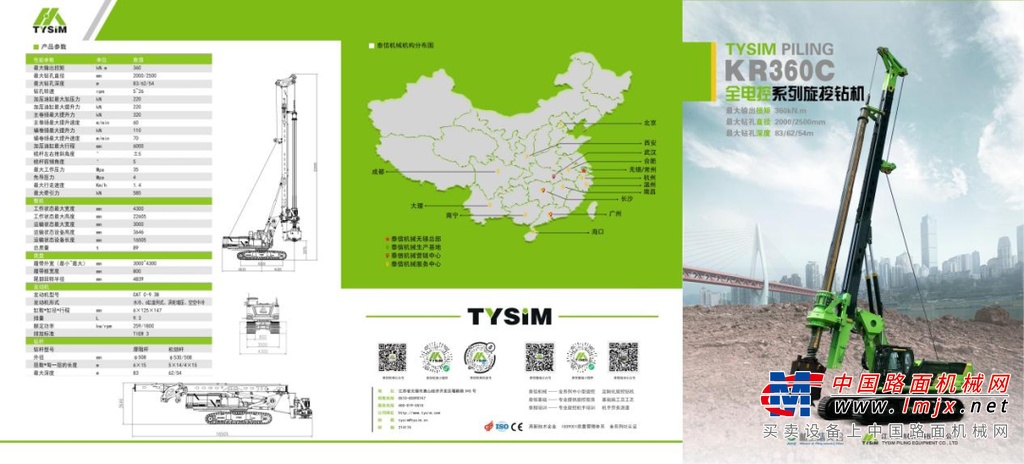

近日,在乌兹别克斯坦纳曼干桥桩项目施工现场,由江苏泰信机械股份有限公司(以下简称“泰信机械”)研发制造的卡特彼勒底盘 KR360C 旋挖钻机正高效运转,为这座当地备受瞩目的桥梁建设奠定坚实基础。该项目的顺利推进,不仅展现了中国桩工机械的卓越性能,更凸显了中国基建及桩工行业在全球市场的重要地位。

Recently, at the bridge pile project construction site in Namangan, Uzbekistan, the Caterpillar chassis KR360C rotary drilling rig developed and manufactured by TYSIM Piling Equipment Co., Ltd. (hereinafter referred to as "Tysim") is operating efficiently, laying a solid foundation for the construction of this highly anticipated bridge in the local area. The smooth progress of this project not only demonstrates the outstanding performance of Chinese pile driving machinery but also highlights the significant position of China's infrastructure and pile driving industry in the global market. Please provide the text you would like translated.

复杂工程挑战重重

Complex engineering challenges

纳曼干大桥作为乌兹别克斯坦重点交通基础设施项目,主体预计 2025 年底竣工,建成后将成为该国最长桥梁。项目桩径 1.5 米,桩长 17 米,甲方对施工设备和工艺提出了极高要求。同时施工现场的地质条件复杂,0 ~8 米为卵石沙层,8 ~ 17 米则是密实卵石沙层,给项目施工带来了巨大挑战。

As a key transportation infrastructure project in Uzbekistan, the Namangan Bridge is expected to be completed in 2025 and will become the longest bridge in the country. The pile diameter of the project is 1500mm, and the piling depth is 17 meters, which places extremely high demands on construction equipment and technology. The geological conditions at the construction site are complex, with a pebble sand layer from 0 to 8 meters and a dense pebble sand layer from 8 to 17 meters, It brought huge challenges to the project construction.

先进设备脱颖而出

Advanced equipment stands out

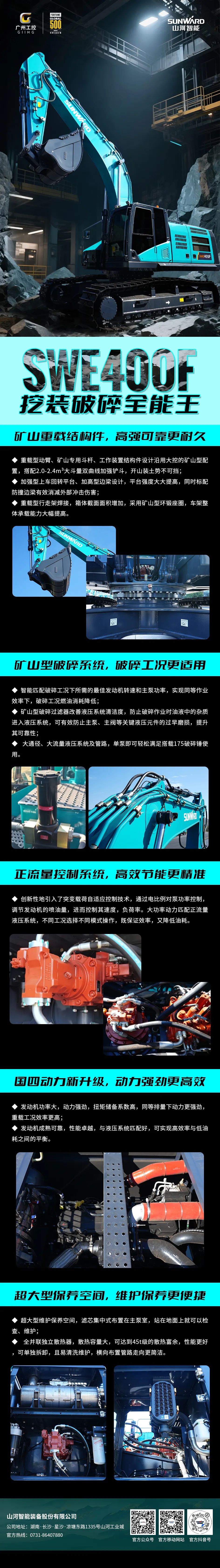

在此背景下,泰信机械研制的卡特彼勒底盘KR360C旋挖钻机脱颖而出。该设备具备强大的扭矩和提升力,能够轻松应对不同地层的钻进需求。在此次项目中,泰信机械全资子公司泰恒基础派出专业团队提供项目管理和工法支持,现场采用泥浆护壁施工工艺,有效确保了孔壁的稳定性。值得一提的是,其成孔时间仅需 2.5小时,相比其他品牌施工设备,效率大幅提升,极大地缩短了项目工期。施工团队严格控制泥浆的比重、黏度等参数,使其能够在复杂地层中形成稳定的护壁,防止塌孔等问题的发生。同时,泰信卡底钻机的精准定位和高效钻进,与泥浆护壁工艺完美配合,进一步提高了施工质量和效率。

In this context, the Caterpillar chassis KR360C rotary drilling rig developed by Tysim stood out. This equipment has powerful torque and lifting capacity, enabling it to easily meet the drilling requirements of different soil layers. In this project, Tysim wholly-owned subsidiary Tyhen Foundation dispatched a professional team to provide project management and construction method support. On-site, the mud wall protection construction method was adopted, effectively ensuring the stability of the hole wall. It is worth noting that the drilling time for this project was only 2.5 hours, which significantly improved efficiency compared to other brand construction equipment, greatly shortening the project duration. The construction team strictly controlled parameters such as the specific gravity and viscosity of the mud, enabling it to form a stable wall in complex soil layers and prevent problems such as hole collapse. At the same time, the precise positioning and efficient drilling of the Tysim Caterpillar Rotary Drilling Rig, combined with the mud wall protection method, further improved the construction quality and efficiency.

中国桩工行业成果斐然

China's pile engineering achieved remarkable results

中国基建近年来在全球市场取得了显著成就,凭借先进的技术、丰富的经验和高效的执行能力,成为推动全球基础设施建设的重要力量。在桩工行业领域,中国企业不断加大研发投入,推出一系列具有国际竞争力的产品,如泰信机械的卡特彼勒底盘旋挖钻机KR360C,不仅满足了国内市场的需求,还出口到世界各地,为全球基础设施建设提供了强有力的装备支持。

In recent years, China's infrastructure industry has made remarkable achievements in the global market. With advanced technology, rich experience and efficient execution capabilities, it has become an important force in promoting global infrastructure construction. In the field of piling industry, Chinese companies have continuously increased their R&D investment and launched a series of internationally competitive products, such as the Caterpillar KR360C rotary drilling rig of TYSIM, which not only meets the needs of the domestic market but is also widely exported to all parts of the world, providing strong equipment support for global infrastructure construction.

深化合作共绘发展蓝图

Deepen cooperation and draw a blueprint for development

纳曼干桥桩项目的实施,充分运用泰信卡底钻机的性能优势,施工团队严格把控泥浆护壁施工工艺确保了桥桩项目的顺利进行,为纳曼干大桥的如期建成提供了坚实保障。随着 “一带一路” 倡议的深入推进,中国基建和中国桩工行业将继续发挥自身优势,积极参与全球基础设施建设,为促进各国经济发展和互联互通贡献更多的中国智慧和力量。相信在不久的将来,纳曼干大桥将以其雄伟的姿态横跨两岸,成为乌兹别克斯坦交通网络中的重要枢纽,同时也将为泰信机械带来又一市场机遇。

The implementation of the Namangan Bridge pile project fully utilized the performance advantages of the Tysim Caterpillar chassis KR360C rotary drilling rig. Strict control of the mud wall construction process ensured the smooth progress of the bridge pile project and provided a guarantee for the completion of the Namangan Bridge on schedule. With the in-depth promotion of the "Belt and Road" initiative, China's infrastructure and pile construction industries will continue to play their own advantages, actively participate in global infrastructure construction, and contribute more Chinese wisdom to promote economic development and connectivity in various countries. In the near future, the Namangan Bridge will span the two sides with its majestic posture and become an important hub in Uzbekistan's transportation network. At the same time, it will also bring another market opportunity for TYSIM.